Comparing Dust Suppression Technologies: Which is Right for Your Industry?

Dust suppression is a vital component of industrial pollution control. Whether it’s a mining operation, a cement plant, or a manufacturing facility, airborne dust can affect workplace safety, environmental compliance, and operational efficiency. Selecting the right dust suppression technology is key to tackling these challenges effectively.

In this blog, we’ll compare various dust suppression technologies, their advantages, disadvantages, and applications to help you identify the best solution for your industry.

Why Dust Suppression Matters

Uncontrolled dust emissions can lead to:

- Respiratory health risks for workers.

- Increased equipment wear and maintenance costs.

- Regulatory fines for non-compliance with environmental standards.

- Reduced efficiency in material handling processes.

Effective dust suppression ensures cleaner air, a safer work environment, and better operational productivity.

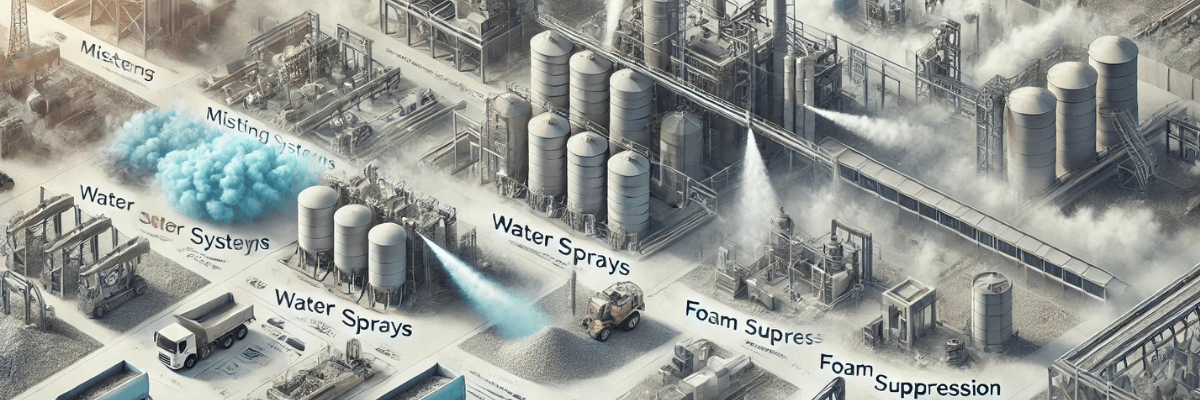

Overview of Dust Suppression Technologies

Here are the most common dust suppression methods:

- Plain Water Sprays

- Ultrasonic Dry Fog Systems

- Chemical-Enhanced Water Systems

- Foam-Based Systems

- Fog and Mist Systems

- Rain Guns and Fog Cannons

1. Plain Water Sprays

How It Works: Plain water is sprayed over the material to increase its weight and cohesion, preventing dust particles from becoming airborne.

Applications:

- Conveyor belts

- Crushing operations

- General material handling

Advantages:

- Simple and low-cost setup.

- Readily available and environmentally safe.

Disadvantages:

- Not effective for hydrophobic materials like coal or coke.

- Excess moisture can cause material buildup on equipment and reduce efficiency in thermal processes.

2. Ultrasonic Dry Fog Systems

How It Works: Ultrasonic nozzles generate ultra-fine droplets (<10 microns), which agglomerate with dust particles of similar size, causing them to settle.

Applications:

- Transfer points

- Cement production

- Dust-sensitive industries

Advantages:

- Minimal water usage (0.01% to 0.05% of material weight).

- Effective for moisture-sensitive materials.

- Low-maintenance and long-lasting nozzles.

Disadvantages:

- Requires high-quality water to prevent nozzle clogging.

- Initial setup costs may be higher.

3. Chemical-Enhanced Water Systems

How It Works: Surfactants are added to water to reduce surface tension, making it easier for droplets to bond with hydrophobic dust particles.

Applications:

- Coal and petroleum coke handling

- Mining operations

- High-dust environments

Advantages:

- Improves water’s dust suppression performance.

- Reduces overall water usage.

Disadvantages:

- Additional costs for chemicals and water treatment.

- May require periodic replenishment of surfactants.

4. Foam-Based Systems

How It Works: Foam is created by mixing water, air, and surfactants, forming a blanket over dusty materials to trap particles.

Applications:

- Crushers and screeners

- Enclosed conveyor systems

- Heavy material transfer points

Advantages:

- Minimal moisture addition.

- Creates a visible barrier to dust.

Disadvantages:

- Requires proper surfactant formulation for effective results.

- More complex setup compared to plain water sprays.

5. Fog and Mist Systems

How It Works: Fine droplets are produced by high-pressure nozzles or compressed air systems to capture airborne dust.

Applications:

- Transfer points

- Crusher operations

- Dust suppression in enclosed areas

Advantages:

- Effective for areas with low turbulence.

- Minimal water usage.

Disadvantages:

- Site-specific and requires precise installation.

- May require enclosures to prevent mist from dissipating.

6. Rain Guns and Fog Cannons

How It Works: Large-scale devices spray water over vast open areas, creating a curtain of droplets to capture dust.

Applications:

- Open-pit mining

- Stockyards

- Construction sites

Advantages:

- Covers large areas efficiently.

- Ideal for outdoor operations.

Disadvantages:

- High water consumption.

- May not be suitable for enclosed areas.

Comparison of Dust Suppression Technologies

| Technology | Water Usage | Best For | Challenges |

| Plain Water Sprays | High | Basic material handling | Excess moisture can reduce efficiency. |

| Ultrasonic Dry Fog Systems | Minimal | Dust-sensitive industries | Higher setup costs, requires filtration. |

| Chemical-Enhanced Systems | Moderate | Hydrophobic materials | Additional costs for chemicals. |

| Foam-Based Systems | Low | Enclosed areas and crushers | Requires surfactant management. |

| Fog and Mist Systems | Minimal | Enclosed transfer points | Requires precise installation. |

| Rain Guns/Fog Cannons | High | Open-pit operations | Not suitable for enclosed areas. |

How to Choose the Right System

1. Identify Your Industry’s Needs:

- Does your material resist water? Consider chemical-enhanced systems.

- Is your operation sensitive to added moisture? Ultrasonic dry fog may be the best choice.

2. Assess the Dust Sources:

- For point-source emissions like crushers, foam systems or ultrasonic fog work well.

- For wide-area suppression, rain guns and fog cannons are effective.

3. Budget and Maintenance:

- Low-cost options like plain water sprays may suffice for less critical operations.

- Advanced systems like ultrasonic fog offer long-term savings despite higher initial costs.

4. Environmental Considerations:

- Fog systems are ideal for environmentally sensitive industries as they minimize water usage.

- Choose systems with minimal chemical usage to align with sustainability goals.