Comprehensive Dust Suppression Systems for Coal Handling Plants

At Dust Suppression Systems Co, we bring over 15 years of specialized experience in designing and implementing advanced dust extraction systems tailored for coal handling plants (CHP) across India. Our innovative solutions not only enhance safety and operational efficiency but also effectively manage coal dust suppression. We prioritize creating a safer working environment for your team while significantly reducing health risks associated with coal dust exposure.

Dry Fog Dust Control Systems

Ultra-fine mist captures dust particles under 10 microns, drastically reducing airborne dust for safer, cleaner environments.

Misting System Suppression

Fine mist spray improves visibility and reduces dust in high-traffic areas, enhancing operational safety and efficiency.

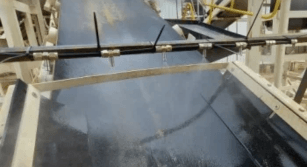

Plain Water Suppression Using Sprinklers

Targeted sprinklers suppress larger dust particles using up to 40% less water than traditional methods, promoting eco-efficiency.

Versatile Applications Beyond Coal Handling

Decreased Chute Blockages – Reduces downtime and maintenance with smoother operations.

FAQ’s

Do you provide complete solutions for dust suppression in coal handling plants?

Yes, we offer comprehensive solutions, including site assessments, system design, supply, integration, and ongoing maintenance of dust suppression systems for coal handling plants.

Can your systems work alongside existing dust collection systems?

Absolutely! Our coal dust suppression systems can be seamlessly integrated with existing dust collection systems, enhancing overall efficiency and coverage.

Will there be any dripping from the nozzles or cannon?

No, our fog cannons are equipped with anti-drip technology to prevent any leakage during operation, ensuring a clean and efficient process.

Is compressed air required for your dust suppression systems?

Yes, our dry fog systems utilize compressed air at a pressure of approximately 4 to 5 kg/cm² (bar) for optimal performance.

How do your dust extraction systems compare to dust suppression systems?

Dust extraction systems are effective in confined areas, while our dust suppression systems provide broader coverage and control over larger areas, making them ideal for extensive operations.